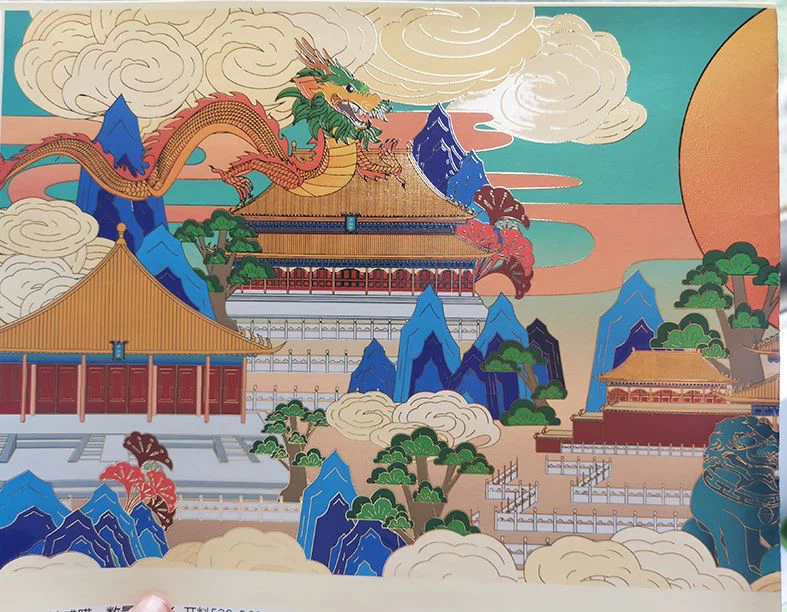

The UV ink of the UV flatbed printer can be printed on any materials, but the adhesion of the various materials is different. The adhesion of plate is better, such as wood, leather. the image is not easy to peel after the inkjet. The adhesion of materials with large density is bad, like glass, crystal, metal, ceramic tile.

To make the ink adhesion of the printed pattern is higher, you can pre- processing and post-processing to increase its adhesion. For example, Before painting, spray a layer of professional coating on the surface of the material, the coating has the effect of increasing the image adhesion, the adhesion of image will be much higher after spraying . Can also print the a layer of varnish on the printed pattern , to isolate the outside world directly touch the image. For the problem of increasing the image adhesion, there are some other technology, such as double-sided glass, the image enclosed in the glass, to achieve the purpose that the image is not peeling off.

After solving the problem of image adhesion, the majority of customers has been troubled by the image is not waterproof. The best way to solve this problem is to use UV flatbed printer spray a layer of professional UV varnish on the printed material, UV varnish not only can increase the adhesion of the image, but also waterproof, So that the beautiful pattern in contact with the water is not easy to peel off.